How Smart Factories Leverage TapData for Real-Time Data Efficiency

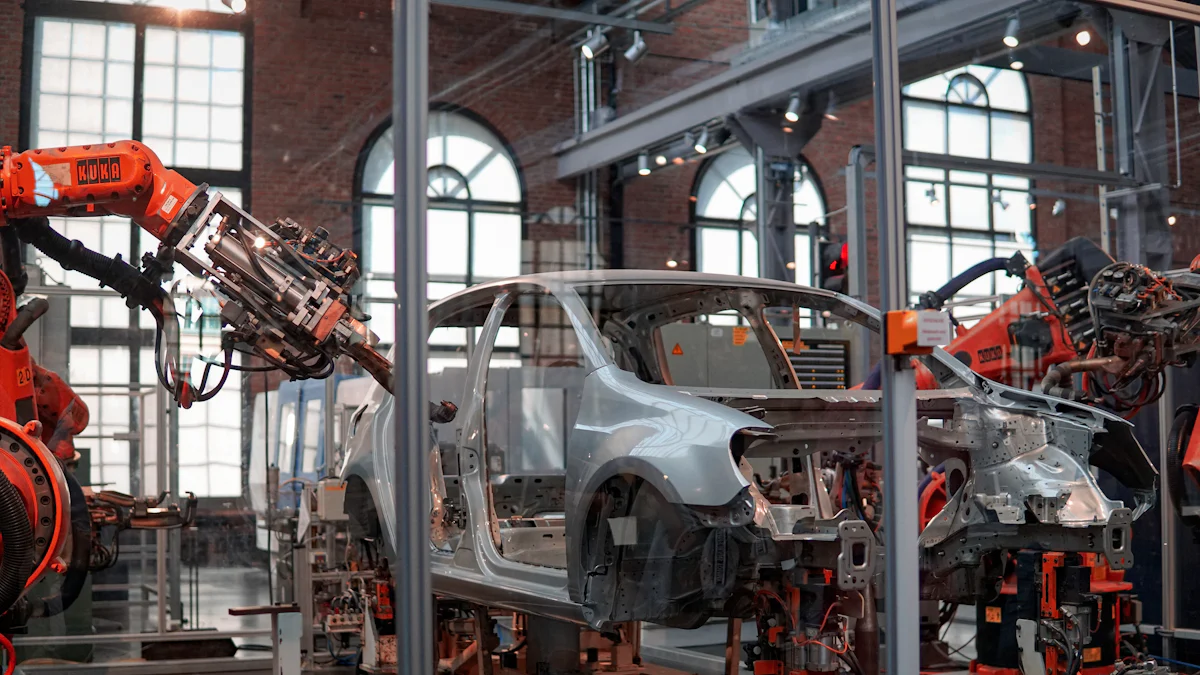

In today’s fast-paced manufacturing landscape, staying competitive demands instant access to actionable insights. Tapdata empowers smart factories by enabling seamless real-time data integration. This platform ensures that critical information flows without delay, allowing you to monitor operations and make informed decisions as events unfold. By leveraging real-time capabilities, you can enhance efficiency, reduce downtime, and adapt swiftly to changing market conditions. Smart factories using Tapdata gain the visibility and control needed to optimize production processes, ensuring agility and long-term success in an increasingly digital world.

Key Takeaways

Real-time data integration is essential for modern manufacturing, enabling immediate access to actionable insights and enhancing operational efficiency.

Tapdata's low-latency data movement allows for seamless synchronization across diverse systems, reducing downtime and improving decision-making.

The platform's compatibility with legacy systems ensures a unified view of operations without disrupting existing processes.

Proactive monitoring and alerting features help detect issues in real time, allowing for swift corrective actions and maintaining system stability.

Implementing Tapdata can lead to significant cost savings by streamlining operations and reducing manual data processing tasks.

Scalability is a key benefit of Tapdata, allowing manufacturers to adapt to growing data volumes and complexity as their operations expand.

Real-world applications of Tapdata demonstrate measurable outcomes, such as reduced downtime and increased productivity, showcasing its impact on manufacturing efficiency.

The Importance of Real-Time Data Integration in Smart Factories

In the evolving world of manufacturing, the ability to access and utilize data in real time has become a cornerstone of operational success. Real-time data integration ensures that you can make informed decisions instantly, adapt to challenges, and maintain a competitive edge. Understanding its importance begins with examining the limitations of traditional methods and the transformative role of real-time solutions.

Challenges of Traditional Data Integration

Traditional data integration methods often rely on batch processing, where data is collected and processed at scheduled intervals. While this approach ensures thoroughness, it fails to meet the demands of modern manufacturing environments. Delayed updates can lead to outdated insights, hindering your ability to respond to time-sensitive issues.

Legacy systems and traditional data warehouses also struggle to handle the complexities of real-time data capture and processing. These systems often create data silos, making it difficult to achieve a unified view of operations. Without real-time data synchronization, you may face inefficiencies, missed opportunities, and slower decision-making processes.

Moreover, traditional methods lack the agility required for today’s fast-paced manufacturing landscape. They cannot provide the continuous and up-to-date data output needed to optimize production processes or detect anomalies as they occur. This limitation underscores the need for a platform that supports real-time data management and processing.

Role of Real-Time Data in Enhancing Operational Efficiency

Real-time data integration transforms how you manage and optimize your operations. By enabling real-time data capture and analysis, you gain immediate access to actionable insights. This capability allows you to identify inefficiencies, address issues proactively, and refine production processes without delay.

With real-time data collection, you can monitor machine performance, track production metrics, and ensure seamless communication between systems. This continuous flow of information enhances operational efficiency by reducing downtime, improving resource allocation, and streamlining workflows.

Real-time data processing also plays a critical role in decision-making. It empowers you to act on current information rather than relying on historical data. For example, detecting equipment malfunctions or supply chain disruptions in real time enables you to implement corrective measures swiftly, minimizing potential losses.

Furthermore, real-time data management supports scalability and future growth. As your manufacturing operations expand, the ability to integrate and process data in real time ensures that your systems remain agile and responsive. This adaptability positions you to stay ahead in an increasingly competitive market.

"Real-time data integration is not just a technological advancement; it is a strategic necessity for modern manufacturing."

By embracing real-time data integration, you unlock the potential to enhance efficiency, improve decision-making, and future-proof your operations. The shift from traditional methods to real-time solutions marks a pivotal step toward achieving smarter, more agile manufacturing processes.

How Tapdata Enables Real-Time Data Integration

Overview of Tapdata's Real-Time Capabilities

Tapdata stands out as a cutting-edge real-time data platform designed to meet the demands of modern manufacturing. Its real-time capabilities allow you to capture, process, and synchronize data across multiple systems without delay. This ensures that your operations always rely on the most current information, enabling faster and more accurate decision-making.

The platform leverages advanced technologies like Change Data Capture (CDC) and stream processing to facilitate low-latency data movement. These features ensure that data flows seamlessly between sources and destinations, eliminating bottlenecks and reducing downtime. Whether you need to replicate databases, integrate IoT device data, or synchronize with cloud data warehouses, Tapdata provides the tools to make it happen in real time.

By offering real-time monitoring and alerting, Tapdata enhances system stability. You can track performance metrics, detect anomalies, and receive instant notifications when issues arise. This proactive approach minimizes disruptions and keeps your manufacturing processes running smoothly. With Tapdata, you gain a reliable and efficient solution for managing real-time data integration.

"Real-time data capabilities are essential for maintaining operational efficiency and staying competitive in today’s fast-paced manufacturing environment."

Key Features Supporting Smart Factory Operations

Tapdata’s robust feature set makes it an ideal data integration platform for smart factories. These features are tailored to address the unique challenges of manufacturing environments, ensuring seamless data management and operational efficiency.

Real-Time Data Synchronization

Tapdata enables continuous synchronization of data across diverse systems. This ensures that your production lines, IoT devices, and legacy systems operate with unified and up-to-date information.Low-Latency Data Movement

The platform excels in minimizing delays in data transfer. By reducing latency, Tapdata supports real-time analytics and decision-making, allowing you to respond quickly to changes in production or supply chain conditions.Compatibility with Diverse Data Sources

Tapdata integrates data from various sources, including ERP systems, and cloud platforms. This flexibility allows you to consolidate data from all aspects of your operations into a single, actionable view.Proactive Monitoring and Alerts

With real-time monitoring, you can oversee the health and performance of your data systems. Instant alerts notify you of potential issues, enabling swift corrective actions to maintain system stability.Scalability for Future Growth

As your manufacturing operations expand, Tapdata scales effortlessly to accommodate increased data volumes. This ensures that your systems remain agile and capable of supporting long-term growth.

These features empower you to optimize production processes, enhance resource allocation, and improve overall efficiency. Tapdata’s real-time data platform not only addresses current operational needs but also positions your smart factory for future innovation and success.

Integration of Tapdata with Smart Factory Systems

Compatibility with Legacy Systems

Integrating modern solutions into existing systems often presents challenges. Tapdata addresses this by ensuring seamless compatibility with both legacy systems. You can connect older infrastructure with cutting-edge technologies without overhauling your entire setup. This compatibility allows you to preserve your existing investments while enhancing operational capabilities.

For example, manufacturers like PepsiCo and BMW have successfully integrated IoT sensors into their production lines. These sensors collect real-time data on equipment performance, energy consumption, and production rates. Tapdata enables you to unify this data with information from legacy systems, creating a comprehensive view of your operations. This unified approach eliminates data silos and ensures that all systems work together efficiently.

By bridging the gap between traditional and modern technologies, Tapdata empowers you to leverage real-time insights without disrupting your current processes. This capability ensures that your manufacturing operations remain agile and adaptable in a rapidly evolving industry.

Minimal Disruption During Implementation

Adopting new technologies often raises concerns about downtime and operational disruptions. Tapdata minimizes these challenges by offering a streamlined implementation process. You can integrate the platform into your existing systems without halting production or compromising efficiency.

The platform’s design prioritizes ease of use and quick deployment. Its real-time data integration capabilities allow you to start synchronizing and analyzing data immediately after setup. This rapid implementation ensures that you can begin optimizing your operations without delay.

Tapdata also provides robust support during the integration process. You receive guidance and tools to address potential challenges, ensuring a smooth transition. This proactive approach reduces the risk of errors and keeps your manufacturing processes running seamlessly.

"Efficient implementation is key to unlocking the full potential of real-time data integration."

By choosing Tapdata, you gain a solution that enhances your operations without causing unnecessary disruptions. This focus on minimal downtime ensures that you can maintain productivity while embracing the benefits of real-time data integration.

Benefits of Real-Time Data Integration with Tapdata

Enhanced Operational Efficiency

Real-time data integration with Tapdata transforms how you manage your manufacturing operations. By enabling continuous data collection and synchronization, the platform ensures that your systems always operate with the most current information. This eliminates delays and inefficiencies, allowing you to streamline manufacturing processes effectively.

For instance, real-time data collection helps you monitor production metrics and machine performance without interruptions. You can quickly identify bottlenecks, optimize workflows, and reduce downtime. This proactive approach leads to increased productivity and improved resource allocation, ensuring that every aspect of your operations runs smoothly.

Tapdata’s ability to unify data from diverse sources further enhances manufacturing efficiency. Whether you’re integrating IoT devices or legacy systems, the platform provides a seamless flow of information. This unified view allows you to make adjustments in real time, keeping your production lines agile and responsive to changing demands.

"Efficiency is not just about speed; it’s about making every process work smarter and more effectively."

By leveraging Tapdata’s real-time capabilities, you unlock the potential to achieve unparalleled operational efficiency, positioning your manufacturing processes for long-term success.

Improved Decision-Making with Real-Time Insights

Access to real-time insights empowers you to make data-driven decisions with confidence. Tapdata’s platform ensures that you always have the most accurate and up-to-date information at your fingertips. This enables you to respond to challenges and opportunities as they arise, rather than relying on outdated or incomplete data.

For example, real-time insights allow you to detect equipment malfunctions or supply chain disruptions immediately. You can implement corrective measures before these issues escalate, minimizing potential losses. This level of responsiveness is critical for maintaining manufacturing efficiency and staying competitive in today’s fast-paced environment.

The platform’s real-time data collection capabilities also support strategic planning. By analyzing current trends and performance metrics, you can identify areas for improvement and allocate resources more effectively. This fosters a culture of continuous improvement, where every decision is backed by reliable, real-time data.

"Real-time insights are the foundation of effective decision-making in modern manufacturing."

With Tapdata, you gain the tools to make informed decisions that drive efficiency, innovation, and growth.

Cost Savings and Scalability for Future Growth

Real-time data integration with Tapdata not only enhances efficiency but also delivers significant cost savings. By streamlining manufacturing processes and reducing downtime, you can lower operational expenses and maximize resource utilization. The platform’s low-latency data movement ensures that every second counts, translating into tangible financial benefits.

Tapdata’s scalability further supports your long-term growth. As your manufacturing operations expand, the platform adapts to handle increased data volumes and complexity. This flexibility allows you to scale your systems without incurring excessive costs or disruptions. Whether you’re integrating new IoT devices or expanding production lines, Tapdata provides a reliable foundation for growth.

Additionally, the platform simplifies data management, reducing the time and effort required for maintenance. One user noted that Tapdata saved them at least 10 hours per week by eliminating the need for manual coding and maintenance. This time savings translates into increased productivity and reduced labor costs, allowing your team to focus on strategic initiatives.

"Scalability and cost-efficiency are essential for sustaining growth in a competitive market."

By choosing Tapdata, you invest in a solution that not only meets your current needs but also prepares you for future challenges and opportunities.

Real-World Applications of Tapdata in Smart Factories

Case Studies Demonstrating Tapdata's Impact

Tapdata has proven its value in real-world manufacturing environments by transforming how factories handle data. One notable example involves a global electronics manufacturer that struggled with fragmented data systems. The company faced delays in accessing production metrics, which hindered its ability to identify inefficiencies. By implementing Tapdata, the manufacturer achieved real-time data synchronization across its systems. This allowed the team to monitor production lines instantly, reducing downtime and improving overall efficiency.

Another case study highlights a food processing company that integrated Tapdata into its operations. The company needed a solution to unify data from IoT sensors and legacy systems. Tapdata’s platform enabled seamless integration, providing a unified view of machine performance and energy consumption. With this real-time insight, the company optimized resource allocation and reduced energy costs by 15%.

These examples demonstrate how Tapdata empowers manufacturers to overcome data challenges. By enabling real-time access to critical information, the platform supports smarter decision-making and operational improvements.

"Real-world applications of Tapdata showcase its ability to drive measurable results in diverse manufacturing scenarios."

Measurable Outcomes and ROI from Tapdata Implementation

The measurable outcomes of Tapdata’s implementation highlight its impact on manufacturing efficiency and profitability. Companies using Tapdata report significant reductions in downtime. For instance, a leading automotive manufacturer reduced machine downtime by 20% after adopting the platform. This improvement translated into higher production rates and increased revenue.

Tapdata also delivers cost savings through streamlined operations. A pharmaceutical company saved over $500,000 annually by eliminating manual data processing tasks. The platform’s real-time capabilities allowed the company to automate data synchronization, freeing up resources for strategic initiatives.

Return on investment (ROI) is another key benefit of Tapdata. Many manufacturers see ROI within months of implementation. For example, a textile company recouped its investment in just six months by leveraging Tapdata to optimize supply chain operations. The platform’s scalability ensures that these benefits grow as manufacturing operations expand.

These measurable outcomes underscore the value of Tapdata in driving efficiency, reducing costs, and supporting long-term growth. By adopting this platform, you can achieve similar results and position your factory for success in a competitive market.

Future of Smart Factories with Real-Time Data Integration

Trends in Real-Time Data Utilization

The future of smart factories revolves around the growing reliance on real-time data. As industries embrace digital transformation, the ability to access and analyze data instantly has become a cornerstone of modern manufacturing. Real-time data utilization is no longer a luxury; it is a necessity for staying competitive in an ever-evolving market.

One significant trend is the integration of real-time data into predictive maintenance. By continuously monitoring equipment performance, you can identify potential issues before they escalate into costly breakdowns. This proactive approach minimizes downtime and ensures uninterrupted production. For example, industries like shipbuilding have already demonstrated how real-time data enhances operational efficiency by enabling swift management actions during critical processes.

Another emerging trend is the use of real-time data to optimize supply chain operations. With instant access to inventory levels, production schedules, and delivery timelines, you can make informed decisions that reduce delays and improve overall efficiency. This level of agility is essential for meeting customer demands and adapting to market fluctuations.

Real-time data also plays a pivotal role in quality control. By analyzing production metrics as they occur, you can detect anomalies and implement corrective measures immediately. This ensures consistent product quality and reduces waste, which is vital for maintaining customer satisfaction and achieving sustainability goals.

"Real-time data analysis is becoming a prerequisite for remaining competitive in the manufacturing industry."

— Signum Solutions

As these trends continue to evolve, the adoption of real-time data will shape the future of manufacturing. It empowers you to enhance efficiency, reduce costs, and make smarter decisions, positioning your operations for long-term success.

How Tapdata Supports Innovation in Manufacturing

Tapdata stands at the forefront of digital transformation, offering a platform that revolutionizes how you manage and utilize real-time data. Its advanced capabilities enable you to harness the full potential of real-time insights, driving innovation and efficiency in your manufacturing processes.

The platform’s ability to integrate data from diverse sources, including IoT devices and legacy systems, ensures a seamless flow of information. This unified approach eliminates data silos and provides you with a comprehensive view of your operations. By leveraging this real-time visibility, you can identify opportunities for improvement and implement innovative solutions that enhance productivity.

Tapdata also supports automation, a key driver of innovation in manufacturing. By automating data synchronization and analysis, the platform reduces manual tasks and frees up resources for strategic initiatives. This not only improves operational efficiency but also fosters a culture of continuous improvement.

Furthermore, Tapdata’s scalability ensures that your systems can adapt to future challenges and opportunities. As your manufacturing operations expand, the platform grows with you, accommodating increased data volumes and complexity. This flexibility positions you to stay ahead in a competitive market and embrace new technologies as they emerge.

"Real-time data capabilities are essential for maintaining operational efficiency and staying competitive in today’s fast-paced manufacturing environment."

By choosing Tapdata, you gain a powerful tool for driving digital transformation. Its real-time data integration capabilities enable you to innovate, optimize, and thrive in the dynamic world of modern manufacturing.

Tapdata empowers you to transform your manufacturing operations with real-time data integration. The platform ensures seamless data flow, enabling you to make faster, smarter decisions while optimizing efficiency. Its advanced features, such as low-latency data movement and compatibility with diverse systems, make it an essential tool for staying competitive in today’s fast-paced market. By adopting Tapdata, you unlock the potential for innovation, scalability, and long-term success. Explore how this cutting-edge solution can revolutionize your smart factory and position your business for a data-driven future.

FAQ

Why should you choose Tapdata?

Tapdata helps you overcome the challenge of disconnected systems like ERP, CRM, IoT, and SaaS. These isolated systems often create data silos, making it hard to unlock the full potential of your data. Tapdata’s real-time database synchronization and ETL processing capabilities bridge these gaps. It connects your systems, collects and processes data, and ensures that your business can access core enterprise data instantly.

What are the key advantages of adopting Tapdata?

Tapdata offers several benefits that make it a standout solution for real-time data integration:

Extensive Data Source and Target Support: With over 100 built-in data connectors, Tapdata ensures stable and efficient real-time data collection and transmission.

Ease of Use: The platform is lightweight, low-code, and ready to use out of the box. Its visual interface allows you to handle complex data integration tasks without needing advanced programming skills.

Enhanced Real-Time Efficiency: Tapdata delivers second-level response times and stable real-time data services, ensuring high efficiency.

Customizable Task Management: You can label and classify data and tasks, making cross-department collaboration and maintenance more manageable.

Data Consistency Verification: The platform includes built-in tools to ensure data accuracy and consistency.

Real-Time Monitoring and Alerts: Tapdata provides over 20 observability indicators, enabling you to monitor task statuses and address issues immediately.

How does Tapdata handle legacy systems and IoT devices?

Tapdata seamlessly integrates with both legacy systems and IoT devices. It connects older infrastructure with modern technologies, eliminating the need for a complete system overhaul. This compatibility ensures that you can unify data from diverse sources, creating a comprehensive view of your operations without disrupting existing processes.

Is Tapdata suitable for non-technical users?

Yes, Tapdata is designed with simplicity in mind. Its low-code, visual interface allows non-technical users to perform complex data integration tasks. Features like data model previews and drag-and-drop functionality make it accessible to users without programming expertise.

How does Tapdata ensure data consistency?

Tapdata includes platform-level data verification tools to maintain data consistency. These tools automatically validate data during synchronization and integration processes, ensuring that your information remains accurate and reliable.

Can Tapdata scale with growing business needs?

Tapdata is built to scale effortlessly. As your business grows and data volumes increase, the platform adapts to handle the added complexity. Its scalability ensures that your systems remain agile and capable of supporting long-term growth.

What kind of monitoring and alerting features does Tapdata offer?

Tapdata provides robust real-time monitoring and alerting capabilities. With over 20 observability indicators, you can track task statuses and system performance. Instant alerts notify you of potential issues, allowing you to take corrective action quickly and maintain operational stability.

How does Tapdata improve operational efficiency?

Tapdata enhances efficiency by enabling real-time data synchronization and analysis. It eliminates delays, reduces downtime, and streamlines workflows. By unifying data from various sources, the platform ensures that your operations run smoothly and adapt quickly to changing demands.

What industries benefit most from Tapdata?

Tapdata is versatile and supports a wide range of industries, including manufacturing, logistics, retail, and healthcare. Any organization that relies on real-time data for decision-making and operational efficiency can benefit from Tapdata’s capabilities.

How quickly can Tapdata be implemented?

Tapdata offers a streamlined implementation process. Its design prioritizes ease of use and quick deployment, allowing you to start synchronizing and analyzing data immediately. This rapid setup minimizes downtime and ensures that you can begin optimizing your operations without delay.

See Also

Harness ClickHouse For Real-Time Data Insights With Tapdata

Exploring Data Integration Strategies To Boost Business Success

Best Data Integration Solutions For Efficient Workflows In 2024

Facilitating Instant Data Transfers Across Different Systems